THIS IS YOUR GUN

THE CALIBER .50

BROWNING

MACHINE GUN M2

AIRCRAFT, BASIC

With brief instructions on the caliber .30 machine gun and caliber .45 automatic pistol

THIS IS YOUR GUN

|

|

|

Restricted

G-1

The standard United States aerial gun—your gun—is the air-cooled caliber .50 Browning machine gun.

Your job is to become enough of a machine gun expert to use and care for the gun properly and to make emergency repairs—so that no attacking fighter will ever catch you unable to fight back. This book and your instructors will show you how to do the job. The first dozen pages are a general introduction to the gun. They define some of the words used in describing it. They identify the major groups of parts and tell how to take them out of the gun. They show briefly how the gun works and how to load, fire, and unload it safely.

The rest of the machine gun section discusses in detail every important part of the gun and the function it performs. It explains in pictures how to take the gun completely apart, how to adjust it, clean it, and oil it, and how to mount it on the adapter that holds it while it is firing.

As a final preparation for combat, the book tells how to load the ammunition, how to check the gun regularly for wear or damage, and how to locate the cause of trouble if the gun stops firing.

Brief descriptions of the caliber .30 machine gun and the caliber .45 automatic pistol, which aerial gunners also use at times, are added.

GUN TALK

. . . terms and definitions you should know.

Your gun fires 750 to 850 shots a minute—14 shots a second. The bullets, weighing nearly two ounces each, leave the barrel at 1,977 miles an hour—2,900 feet a second. This speed is called the muzzle velocity. Even at a distance of four miles—the gun's maximum range—one of those bullets will kill a man.At closer distances, the bullets wreck anything that gets in the way. In tests on the proving ground, the caliber .50 smashes through the metal skin and framework of an airplane, drills through a metal ammunition box, penetrates a hard pine board—and still has enough power left to pierce a plate of armor nearly a half inch thick.

Yet the gun is light—only 64 pounds—and small enough to fit into almost any airplane. The gun is an automatic weapon. After the first cartridge is loaded and the gun is cocked—an operation called charging—it will keep firing as long as the trigger is held down. A semi-automatic weapon, like the caliber .45 pistol, fires only one shot each time the trigger is squeezed.

Your caliber .50 is a free, or flexible gun—mounted so that it can be swung from side to side or up and down to fire in any direction. A fixed gun, like the machine guns in the wings of a fighter plane, cannot be moved—the whole plane must be turned to aim the gun. The aircraft caliber .50 gun is air-cooled — air, circulating through the holes in the barrel jacket, keeps the barrel from heating up too fast. This system is effective because

Restricted

G-2

the air at high altitudes is very cold and the gun is sticking out into the slipstream. On the ground, the air-cooled gun heats up more rapidly and long bursts cannot be fired without damaging the barrel. Machine guns designed for ground use are water-cooled, or have a heavy barrel that can stand more heat.

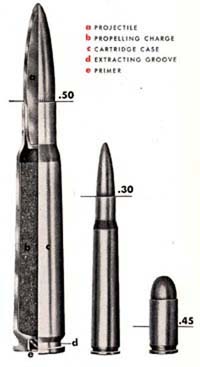

Along the inside of the barrel—called the bore—are twisting grooves. The wide ridges between the grooves are called lands, and the grooves and lands together are called the rifling. It makes the bullet spin like a football in a good forward pass. Without it, the bullet would travel like a wobbly pass and the gun would lose most of its accuracy. The caliber of any gun is the distance across the inside of the barrel, measured from land to land. Your gun is a caliber .50 because the barrel is 50/100ths of an inch wide —in other words, half an inch. The bullet is a hair's breadth wider than half an inch. This makes for a tight fit which prevents any force from escaping when the shot is fired, and also squeezes the bullet into the grooves.

The cartridge, or round, is exactly the size of the cutaway diagram. While it is being fired, it is held in an enlarged opening called the chamber at the rear of the barrel. The cartridge case is simply a metal shell. Near its base it has an extracting groove so that parts inside the gun can pull it out of the ammunition belt and then pull it out of the chamber after it has been fired. Inside the case are the primer and the propelling charge. The primer is a small charge of high explosive which goes off when the gun's firing pin strikes it. This sets fire to the propelling charge, which burns out in a flash and sends the bullet, or projectile, on its way.

The cartridge, or round, is exactly the size of the cutaway diagram. While it is being fired, it is held in an enlarged opening called the chamber at the rear of the barrel. The cartridge case is simply a metal shell. Near its base it has an extracting groove so that parts inside the gun can pull it out of the ammunition belt and then pull it out of the chamber after it has been fired. Inside the case are the primer and the propelling charge. The primer is a small charge of high explosive which goes off when the gun's firing pin strikes it. This sets fire to the propelling charge, which burns out in a flash and sends the bullet, or projectile, on its way. The gases created by the propelling charge set up the terrific chamber pressure of 50,000 pounds, or 25 tons, per square inch inside the cartridge case—as much force as a medium tank balanced on a man's thumb. Some of this force is absorbed

by the barrel. Five tons drive the bullet forward. Another five tons give a backward

kick— the recoil—to the empty case and some of the gun parts.

After the recoiling parts are driven back as far as they can go, they bounce

against springs and buffers that start them forward again. This forward movement

is the counter recoil. As soon as the moving parts have returned to place,

the gun is back in battery position and ready to fire again. To feed into

the gun, the cartridges or rounds are hooked together with metal links

to form a long ammunition belt. By changing certain parts of the gun, you can

feed the belt from either side. After each shot, the empty cartridge case is pushed

out the bottom of the gun, while the used links are tossed out to one side. |

|

Restricted

G-3

1 Back Plate Group

2 Bolt Group

3 Oil Buffer Group

4 Barrel Group

5 Cover Group

6 Retracting Slide Group

7 Casing Group

The explosion touched off by the pressure of your finger on the trigger sets about 150 working parts in motion. While the gun fires, parts are recoiling and counter recoiling, locking and unlocking, compressing and expanding, pivoting, sliding, pushing, pulling, opening, closing.

At first glance, the gun and its workings look as complicated and puzzling as fine clockwork. Fortunately, the parts fall naturally into seven main groups. It is easy to learn to recognize the seven groups and then learn the parts within each group.

Restricted

G-4

The bolt group is the hardest worker of the team. Shuttling from battery position to the rear of the gun and back again about 14 times a second, the bolt group draws the live rounds from the ammunition belt, loads them into the chamber, and hits them with the firing pin. It pulls empty cases from the chamber and tosses them out the bottom of the gun.

The barrel group includes the barrel and the barrel extension that screws onto it. This group also recoils, but not nearly so far as the bolt group.

The oil buffer group is the brake that stops the recoiling barrel group. Its main part is a sealed cylinder full of oil. When the barrel and barrel extension recoil, they drive a piston into the cylinder, forcing the oil through two slots in the side of the piston head. The impact of the barrel and barrel extension is so powerful that all the oil is forced through the slots in a small fraction of a second.

The casing group encloses all the parts of the gun. It includes the receiver, which is a rectangular steel box holding the working mechanism, and the barrel jacket, which supports and protects the barrel.

The retracting slide group, which can be mounted on either side of the receiver, is used to charge the gun for the first shot.

The cover group, which encloses part of the top of the receiver, does most of the work of feeding the ammunition belt into the gun.

The back plate group, at the rear of the receiver, absorbs the force of the bolt's recoil.

This general knowledge of the seven groups is sufficient for a preliminary understanding of how the gun works. For a brief explanation of what happens inside the gun, turn the page.

Restricted

G-5

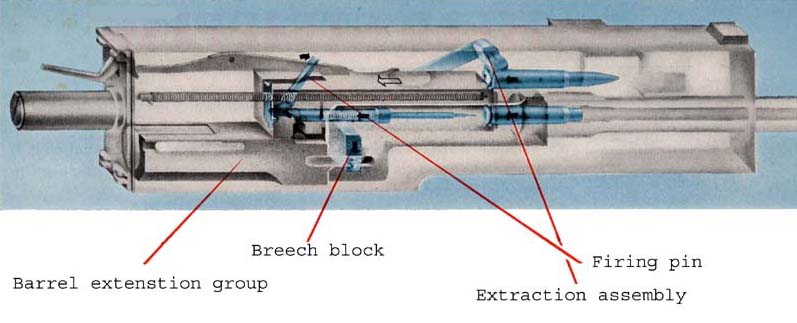

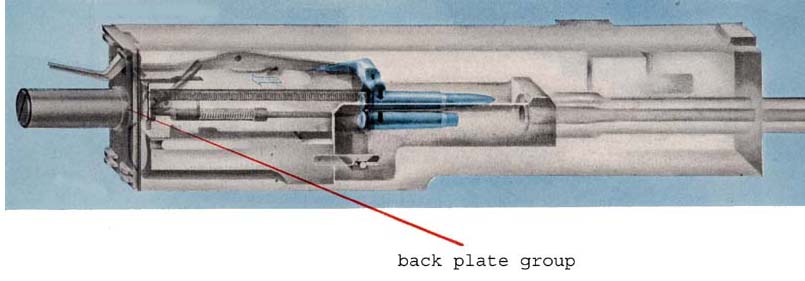

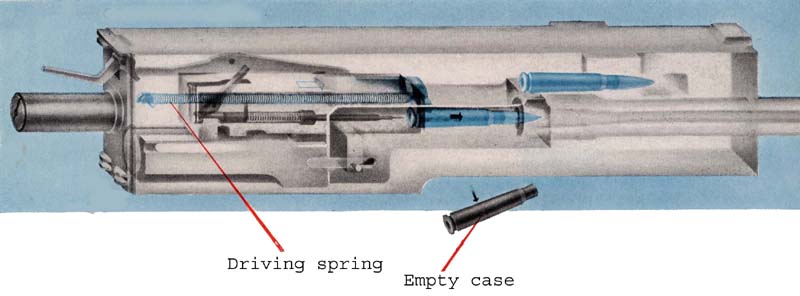

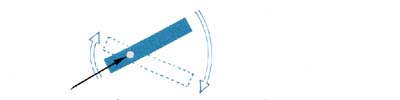

These simplified diagrams give a general picture of how the gun operates. They show the three recoiling parts—bolt, barrel, and barrel extension-—going through a complete cycle from battery position through recoil and counter recoil. Many other parts not shown here are, of course, performing their jobs at the same time. The complete picture, called the cycle of operation, is described on pages G-52 to G-62.

READY TO GO

The gun is in battery position, set to fire. One round is in the chamber; the next round is in the feedway ready to be moved into place. The firing pin, drawn back against its spring, is held back by a notch at the bottom of the sear. Bolt and barrel extension are locked together by the breech block

FIRE

When the trigger is pressed, the front of the trigger bar presses down the sear and unlocks the notches. The firing pin, driven by its spring snaps forward. The gun fires. The force of the explosion drives the bold, barrel, and barrel extension backward.

Restricted

G-6

|

|

| The breech lock is forced down, unlocking the bolt. The barrel extension is stopped by the oil buffer group, but the unlocked bolt keeps going back. The cocking lever pivots, pulling the firing pin back against its spring and hooking it onto the sear notch. The extractor assembly draws the next round from the feedway. The empty case, held in a slot in the front end of the bolt, is pulled from the chamber. |

|

|

| The bolt travels back until it hits the back plate group. The extractor assembly carries the new round back and down toward the chamber. |

|

|

| Aided by its driving spring, the bolt bounces forward. We extractor assembly pushes the new round farther down, forcing the empty case out of the gun, and then starts to feed the new round into the chamber. The next round moves into the feedway. |

| RETURN TO BATTERY POSITION As the bolt goes forward, the breech lock moves up to lock the bolt to the barrel extension, and the bolt and barrel extension return together into battery position. The extractor assembly reaches up to grab the next cartridge in the feedway. The new round is pushed into the chamber by the bolt. The gun is ready to fire again. |

Restricted

G-7

Removing the groups from the gun, without taking the groups themselves apart, is called field stripping.

It is the first step in taking the gun completely apart to clean and oil it. If a gun stops firing, field stripping is the way to get at the working parts to

see what is wrong.A gunner in combat field strips his gun every day. These pictures show the steps.

STRIPPING

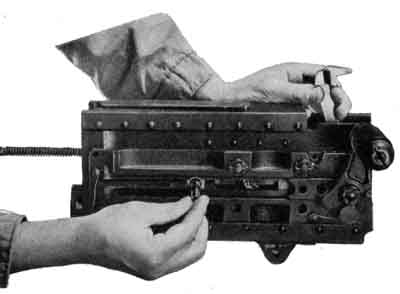

Raise the Cover.

Turn the cover latch and swing the rear end of the cover up and forward.

Make sure

that the gun is in

battery position.

The lips of the T-slot should be against the breech end of the barrel, and the barrel extension against the trunnion block. Never remove the back plate unless the bolt is in battery position. When the bolt is back, the driving spring is compressed and might shoot out of the receiver with terrific force.

Next raise the extractor assembly with your left hand and look down the T-slot to see if there is a round in the chamber—it might be a live one. Live or dummy, remove it.

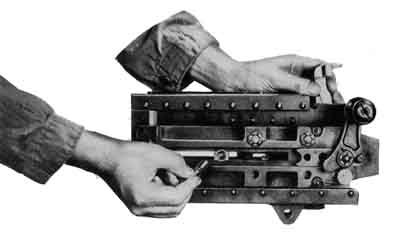

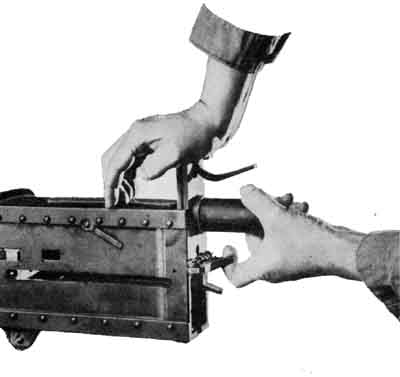

Remove the back plate.

Hold down the top of the receiver with one hand and put your other hand in the position shown here. Pull the latch lock back with your middle finger, lift up the latch with your forefinger, and slide the back plate up out of the receiver.

Restricted

G-8

Remove

the driving spring. |

|

|

Remove

the bolt stud. |

|

Remove

the bolt group. |

Release

the firing pin. |

|

Restricted

G-9

|

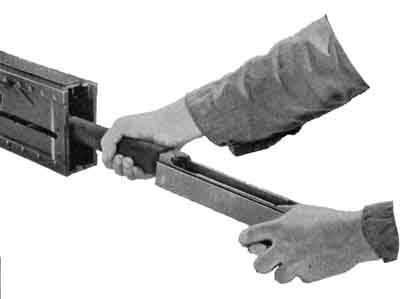

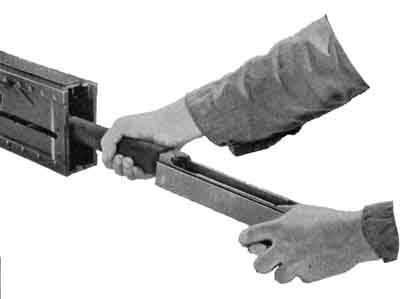

Pull

out the oil buffer and barrel groups. |

Separate

the oil buffer group from the barrel group. |

|

|

Remove

the barrel group from the receiver. |

| ASSEMBLY |

|

Put

the barrel group part way into the receiver and attach the oil buffer group. |

Restricted

G-10

Replace

the bolt group and push the groups into the receiver. |

|

|

Replace

the bolt stud. |

Seat

the driving spring. |

|

|

Replace

the back plate. |

Restricted

G-11

Operating the gun, when it is properly set up and in good working order, is almost as easy as using a rifle. The methods shown here are simple, correct—and safe. They are designed to prevent accidents. Make a habit of doing the steps in this order.

CHARGING Charging the gun—by pulling back the charging handle— cocks the firing pin. When there is an ammunition belt in place, it also moves a round from the feedway into the chamber, and moves the next round in the belt into place against the cartridge stops. Before the gun is loaded, charge it once without any ammunition in it and press the trigger to make sure the firing mechanism works. You should hear a click as the firing pin snaps forward. There is no use loading a gun that won't fire. The correct way to charge the gun is also the easiest way: 1 Mold the grip with your palm up. 2 With one smooth and rapid movement, pull back and down on the grip, draw it all the way back, and let go. Pull hard and fast. A strong, steady pull may not break the gun out of battery. A strong, quick pull will. 3 Don't stop pulling when the grip is all the way back. Your arm should come back with such force that it keeps traveling back after the grip is forced out of your palm. This bounces the bolt against the back plate and helps the driving spring force it fully forward into battery position. Above all, don't hold on to the grip and ride it forward. LOADING > Every gun you fire will be mounted in an adapter. After charging the gun to test the firing mechanism, put the safety on the adapter in the SAFE position while loading the gun.

Always feed the ammunition belt into the gun with a double link entering first.

To load a hand-held gun, or a turret gun whose cover can be raised:

1 Raise the cover and lift up the extractor assembly.

RestrictedG-12

2 Put the first round firmly against the cartridge stops, with the double loop of the link projecting beyond the stops. 3 Put the extractor assembly down, see that its hook is in the extracting groove of the round, and close the cover, making sure it is latched. 4 Charge the gun once. This will move the first round from the feedway into the chamber.

To load a gun when you cannot raise the cover: 1 Push the end of the belt into the feedway until the first round is held in place by the belt holding pawl—the little catch on the bottom of the feedway. 2 Charge the gun twice. The first charging will move the round over against the cartridge stops, the second charging will move it into the chamber.

FIRING To fire, squeeze the trigger and hold it back as long as you want the gun to keep firing. If the adapter has two triggers, you can fire by squeezing either of them or both. The correct position of your head, arms, and body will be demonstrated on the firing range.

UNLOADING

To unload the gun before the ammunition belt is used up: 1 Raise the cover, lift the extractor assembly, and pull out the ammunition belt. If you have trouble removing the ammunition belt, shake it. 2 Charge the gun twice. The first charging will move the round over against the cartridge stops, the second charging will move it into the chamber. 3 Pull the bolt back and look into the T-slot and chamber to make sure they are empty. To make doubly sure, charge the gun once more. 4 Pull the trigger to release the firing pin. Put the safety on the adapter in the SAFE position.

When you continue firing until all the ammunition is used: 1 Pull back the bolt and make sure the T-slot and chamber are empty. Charge the gun once to be doubly sure. 2 Pull the trigger to release the firing pin. Put the safety on the adapter in the SAFE position.

RestrictedG-13

SAFETY RULES

Never forget that a caliber .50 machine gun is essentially a terrific explosion wrapped up in a metal package.

When the gun is handled properly, it controls that explosion so that nobody can be hurt but the enemy.

But one instant of carelessness may release that packaged power at the wrong time, or in the wrong direction.

Never let that happen to you. Make these safety rules your safety bible.

Before Loading the Gun

Make sure the barrel is free of obstructions and excess oil.

Make sure the cover and back plate are securely latched.

Test the operation of the gun with dummy ammunition, or by hand charging and "dry firing" without any ammunition in the gun.

Put the safety on the adapter in the SAFE position.While Firing the Gun

If, while you are pulling the trigger, the gun stops firing before the ammunition is used up, beware of a delayed explosion. Wait 10 seconds before charging the gun or raising the cover.

Never use a metal tool to pry a live round or an empty case out of the gun.After Unloading

Make sure the chamber and T-slot are empty by charging the gun twice.

Release the firing pin and put the safety on the adapter in the SAFE position.In the Shop

Check the chamber and T-slot before starting to work on the gun.

Never charge the gun against the pressure of the driving spring when the back plate is off.

Keep your fingers out of the gun when charging it with the cover raised.

Never try to force the parts when stripping or assembling the gun.

Make sure the cocking lever is forward before replacing the bolt in the receiver.

Make sure the bolt is in battery position before closing the cover.

Never lay a gun down where it may fall.

RestrictedG-14

The preceding pages have given about as much information on the machine gun as the average automobile driver knows about his car—enough to use it provided a mechanic is always available to take care of it and make repairs. As a gunner, however, you must be your own mechanic. The following pages present the additional knowledge that spells the difference between amateur and expert.

Taking the gun completely apart—first removing the seven groups and then breaking each group down into its parts—is called detail stripping.

Your gun must be detail stripped after every firing mission so that you can get at every smallest part to clean it, oil it, check it for wear or damage, and replace it if necessary. In a combat zone, you may have to do this job before dawn, in a tent without heat or light. In school, therefore, you will learn to detail strip the most important groups—all but the back plate and retracting slide—while blindfolded and wearing gloves.

A caliber .50 combination wrench can be used for the job, although it was designed to perform some adjustments ordinarily handled only by ordnance personnel and is therefore too clumsy for general use. It is easier to use a caliber .30 combination tool, or even a screwdriver and a nail or cartridge

Those Terms are used again and again in describing details of the gun:

Pivot

a pin or stud on which some other part turnsCam

a slanted surface which changes the direction of a moving part.Pawl

a catch which lets a moving part go in one direction.Bevel

a slanted surface made by cutting off a square edge.Drift

any pointed object used to push a pin out of its hole.

RestrictedG-15

Cotter Pin are used in many of the gun's pins and nuts to make sure they will not loosen or fall off. In classroom practice it is customary to use the same cotter pins again and again. In a combat zone, however, new cotter pins should be installed, if possible, while assembling the gun after stripping and cleaning it. Worn cotter pins may break or fall out. Cotter pins are used in several sizes. Wherever you insert a cotter pin, use the largest one that will fit into that hole, but be sure it is not so long that it will interfere with working parts.

Insert cotter pins so that their heads will be up when the gun is assembled. Bend the ends of cotter pin so that they will not interfere with working parts of the gun, or snag clothing and equipment. Separate the tips, and use pliers or some other tool to bend them around the nut or pin. If there are grooves in the side of the nut, bend the tips' of the cotter pins into the nearest grooves.

In some cases, it is more convenient to insert the cotter pin so that one end can be bent up over the end of a pin or stud, and the other end bent down into one of the grooves in the nut.Safety Wiring is also used to keep nuts and screws from loosening. The wire should go around the nut in such a direction that a pull on the wire will tighten the nut. To safety wire two nuts:

Put one end of the wire through the hole in the first nut, bring it around the side of the nut, and twist the two ends of the wire together. Pull the twisted wire around the nut in the direction that tightens the nut and twist together a section long enough to reach the second nut.

Put one end of the wire through the hole in the second nut in such a direction that a pull on the twisted part of the wire would tighten the nut. Continue the other end around the nut, twist the two ends together for a short distance, cut them off, and tuck them out of the way. Making the Job Easy The photographs on the next 34 pages show every step of detail stripping for all seven groups.

With each photograph are full instructions for performing the step. The groups are presented in the order they are normally removed from the gun:

1. Back Plate 2. Bolt 3. Oil Buffer 4. Barrel 5. Cover 6. Retracting Slide 7. Casing

Instructions for each group are preceded by a list of the nomenclature and functions of all its parts.

The function lists are for reference: when you start to learn detail stripping, do not attempt to read and memorize them.

As each part is removed, its function is explained in more detail. In a description of the cycle of operation on pages G-52 to G-62, all the parts are shown performing their functions as the gun operates. After you know the cycle of operation, the function lists will be easy to understand and

can be used for review.

RestrictedG-16

BACKPLATE GROUP

Nomenclature Function

1 BUFFER ADJUSTING SCREW Adjusts the pressure on the buffer disks. 2 BUFFER ADJUSTING SCREW

PLUNGER AND PLUNGER SCREWPrevent the buffer adjusting screw from turning freely. 3 BUFFER DISKS Absorbs shock of the bolt's recoil. 4 BUFFER PLATE Passes the shock of the bolt's recoil on to the buffer disks and prevents battering of the back plate. 5 TRIGGER Raises the rear end of the trigger bar, making the front end press down on the sear to release the firing pin and fire the gun. 6 TRIGGER SPRING Returns the trigger to position. 7 SPACER Keeps the trigger the proper distance from the side. 8 TRIGGER PIN Holds the trigger and provides a pivot for it. 9 BACK PLATE FILLER PIECE Fills the trigger hole when the trigger is not installed. 10 LATCH LOCK Locks the latch. 11 LATCH LOCK PIN AND COTTER PIN The pin holds the latch lock and provides a pivot for if; the cotter pin keeps the latch lock pin in place. 12 LATCH LOCK SPRING AND PIN The spring, which is held in the latch lock by its pin, pushes against the latch lock to hold it in place. 13 LATCH Holds the back plate down. 14 LATCH SPRING Pushes against the latch to keep it locked. 15 LATCH PIN Holds the latch and provides a pivot for it. 16 LOWER FILLER PIECE Provides a mounting for the latch lock. 17 LOWER FILLER PIECE PINS AND COTTER PINS Hold the lower filler piece in position. 18 BACK PLATE Encloses the back end of the receiver, and keeps the oil buffer

group from moving back.19 BUFFER TUBE Houses the buffer adjusting screw, buffer disks, and buffer plate.

RestrictedG-17

STRIPPING Remove the buffer adjusting screw (1).

While unscrewing it, wrap your fingers around it to keep the plunger and plunger spring (2) from jumping out.The buffer adjusting screw regulates the pressure on the buffer disks. The plunger and plunger spring prevent the adjusting screw from turning freely.

Remove the buffer disks (3) and buffer plate (4) by tilting the buffer tube (19) until they fall out.

The buffer plate receives the shock of the bolt's recoil and passes it on to the buffer disks, which absorb it. The buffer plate also keeps the bolt from battering against the back plate.Take out the trigger (5), trigger spring (6), and spacer (7).

After you push out the trigger pin (8) they can easily be removed from the front. (There will be no trigger on the back plate unless the gun has been assembled for use in an adapter.)

The trigger lifts the rear end of the trigger bar. This forces the front end down on the sear, releasing the firing pin and firing the gun. The trigger spring then forces the trigger back into position. The spacer keeps the trigger the proper distance from the side.

RestrictedG-18

Remove the latch lock (10)

by pulling out the cotter pin and drifting out the latch lock pin (11).The latch lock keeps the latch fastened.

Take off the latch (13) and latch spring (14)

by drifting out the latch pin (15). Press the latch with your thumb so its spring will not pop out. The latch, forced into position by its spring, holds the back plate down.Remove the lower filler piece (16)

by taking out the cotter pins and removing the two lower filler piece pins (17). For this step and the next two steps, it is easier to hold the back plate upside down, as shown here.

The filler piece provides a mounting for the latch lock.

RestrictedG-19

ASSEMBLY Replace the lower filler piece.

Insert the filler piece pins with their heads toward the top and replace the cotter pins. If the gun is to be used in an E-l 1 adapter, the filler piece should stick out to the right. Otherwise it can stick out on either side.Replace the latch/ latch spring and latch pin.

Make sure the spring is seated in the holes in the latch and the lower filler piece. Press down on the latch while inserting the pin.Put back the latch lock

and insert its pin and cotter pin.Replace the trigger.

Put it through its hole, with the long handle part to the rear and the hole for the trigger spring on top. Seat the trigger spring in the hole on the trigger and push the top of the spring back into the hole in the back plate. Put the spacer to the left of the trigger (as seen from behind the gun) and push the trigger pin into place.

RestrictedG-20

Replace the buffer plate and buffer disks.

Put the buffer plate into the buffer tube, small end first, and drop in the disks a few at a time... Or, if you are working at a steady table, stack up the disks like poker chips, put the buffer plate on top with the small end up, and push the buffer tube down over the stack.

Replace the buffer adjusting screw.

Put the plunger and plunger spring into the hole in the buffer adjusting screw. Tighten the screw until the plunger hits the buffer tube, then hold the plunger down with the tip of a tool and continue to turn the screw until the plunger is held in place.

Adjust the buffer adjusting screw.

When the screw has been tightened as tight as possible—use the caliber .50 combination wrench if one is available—you should not be able to see more than one thread. If it does not go in that far, you have inserted too many buffer disks, or the disks and the buffer plate are not seated correctly. If the screw goes in so far that the end goes inside the buffer tube, the disks are too worn to be used. Have the ordnance shop make the necessary replacements.

RestrictedG-21

Nomenclature Function

1 DRIVING SPRING ROD ASSEMBLY

a DRIVING SPRING ROD COLLAR PIN STOP

b DRIVING SPRING ROD COLLAR

c DRIVING SPRING ROD

d DRIVING SPRING ROD HEAD AND RETAINING PIN

e OUTER DRIVING SPRING

f INNER DRIVING SPRINGSmooths out the action of the bolt in automatic fire and helps push it forward on counter recoil; returns the bolt to battery position in hand charging. 2 BOLT STUD Connects the bolt to the retracting slide group. 3 EXTRACTOR ASSEMBLY Pulls the new round from the ammunition belt and helps feed it

into the chamber; ejects the last empty case in a belt.a EJECTOR Helps support the new round for extraction from the belt and feeding into the chamber; ejects the last spent case in a belt. b EJECTOR SPRING Holds the ejector against the round. c EJECTOR PIN Holds the ejector in place and provides a pivot for it. d EJECTOR HOOK Extracts the new round from the belt by hooking into the extracting grooves. d EJECTOR LUG Rides under the extractor switch and over the extractor cam to guide the extractor assembly on counter recoil. 4 BOLT SWITCH Provides a clear track along either the right or left cam groove, depending on the direction of feed. 5 BOLT SWITCH STUD Keeps the bolt switch from turning. 6 COCKING LEVER Cocks the firing mechanism; keeps the gun from firing too soon. 7 COCKING LEVER PIN Holds the cocking lever in place and provides a pivot for it.

RestrictedG-22

Nomenclature Function

8 SEAR STOP ASSEMBLY

The sear stop holds the sear in place. Its pin provides a compression point for the firing pin spring. 9 SEAR SLIDE Pushes the sear down to release the firing pin when the gun is

fired from the side.10 SEAR Holds the firing pin back until the trigger is pressed. a SEAR TIP Rides under the trigger bar to cam down the sear in automatic fire. b SEAR NOTCH Hooks into the notch on the firing pin extension to hold the firing pin back until the trigger is pressed. 11 SEAR SPRING Pushes the sear up into place after each round is fired. 12 FIRING PIN ASSEMBLY a FIRING PIN Fires the round by hitting the primer. b FIRING PIN EXTENSIONS ASSEMBLY (1) FIRING PIN SPRING

Forces the pin forward when the trigger is pressed. (2) FIRING PIN SPRING STOP PIN

Holds the firing pin back until the trigger is pressed. (3) FIRING PIN EXTENSION NOTCH

Hooks onto the sear notch to hold the firing pin back until the trigger is pressed. 13 BOLT BODY Houses the parts of the bolt group. Its two cam grooves make it

possible for ammunition to be fed into either side of the gun.a T-SLOT Extracts the spent case from the chamber and helps support the

new round entering the chamber.b RECOIL PLATE Provides a shield of harder metal to receive the recoil of the primer. c FIRING PIN PORT Provides a hole which enables the firing pin to hit the primer. d EXTRACTOR STOP PIN Stops the downward motion of the extractor assembly. e BREECH LOCK RECESS Provides a space for the breech lock to enter the bolt to lock it to the barrel extension. f MIDDLE PROJECTION Turns the accelerator to the rear in hand charging. g LOWER PROJECTION Works with the accelerator to speed up the bolt on recoil and slow it down on counter recoil. h CAM GROOVES Guide the belt feed lever (of the cover group) as its lug rides in the grooves. (Before you start on this group, make sure the firing pin has been released.)

STRIPPING Remove the extractor assembly (3)

by swinging it to the rear and pulling it off the side.

The extractor assembly pulls the new round from the ammunition belt and helps guide it into the chamber. It also ejects the last spent case in a belt.

Remove the ejector (3a) and ejector spring (3b).

After you drift out the ejector pin (3c), the ejector will fall out. The spring may need a little shaking. (If the ejector pin is staked—fastened—in place, do not remove it; let ordnance make-any necessary repairs.)

The ejector, held against the side of the new round by the spring, helps line up the round with the chamber. The ejector also pushes out the last empty case of the ammunition belt—a job ordinarily done by the new round as it is pushed down the T-slot.

RestrictedG-23

Lift out the bolt switch (4) and the bolt switch stud (5).

(In some guns the stud is staked and cannot be

removed.)

The bolt switch con be turned to provide a clear track along either the right or left cam groove. This is one of the adjustments which allows the gun to feed from either right or left. The stud keeps the bolt switch from turning.Remove the cocking lever (6) and cocking lever pin (7)

Pull the pin out to the side with your left forefinger and thumb. At the same time lift up the cocking lever with your right hand.

The cocking lever, pivoting on its pin, cocks the firing mechanism. It also prevents the firing mechanism from acting too soon—a protection called fire control.Remove the sear assembly (8).

Put a pointed tool in the groove at the rear of the

rear of the sear stop. Pry the sear stop over to the

right. The . . .Turn the bolt upside down and push the tool down against the bottom of the sear pin. Finally . . .

RestrictedG-24

Turn the bolt right side up and lift out the sear stop assembly. The sear stop holds the sear in place. The sear stop pin is a compression point for the firing pin spring, which backs up against the pin when the gun is cocked.

Remove the sear slide (9).

Press the sear (10) down with a tool or the thumb of one hand. With the thumb of the other hand, push the slide out sideways, square end first.

The sear slide makes it possible to fire the gun with a solenoid—an electrical attachment—mounted on the side. This is one method of firing turret guns. A plunger in the solenoid pushes in on the square end of the sear slide, camming down the sear.Remove the sear (10) and sear spring (11).

Lift the sear up out of its slot. Turn the bolt upside down and shake out the spring.

The sear holds the firing pin back when the gun is cocked. In firing, the trigger bar presses the sear down t o release the firing pin. The sear spring then forces

the sear back into place.Remove the firing pin assembly (12)

by tilting up the front end of the bolt and shaking it.

.

The firing pin assembly fires the round by driving the pin against the primer.

RestrictedG-25

Separate the firing pin (12a) and firing pin extension assembly (12b)..

Simply lift the firing pin out of the slot in the front of the extension.

The firing pin extension notch hooks onto the sear notch. The firing pin spring drives the firing pin forward. The spring stop pin holds the spring in the firing pin extension.ASSEMBLY Insert the firing pin assembly.

Fit the back end of the firing pin into the notch at the front of the extension assembly. Tilt up the back end of the bolt. Slide the firing pin assembly into the bolt with the firing pin extension notch facing downReplace the sear and sear spring.

Seat the spring in the circular hole in the bottom of the bolt. The easiest way is to put the spring over the point of an extra firing pin or a drift, put the point into the hole, slide the spring into place, and remove the drift. Then slide the sear down into its slots with the sear notch forward. Make sure that the bottom of the spring is seated in the hole in the bolt and that the top is seated in the hole in the bottom of the sear.Replace the sear slide.

Press the top of the sear down with one thumb. With the forefinger and thumb of the other hand, push the slide into place, notch down. If the slide fails to go in easily, check to see if the sear spring is properly seated.

RestrictedG-26

Insert the sear stop assembly.

Tilt the bolt to slide the firing pin assembly all the way forward. Push the sear stop pin into place. Then . . .Put a tool in the groove at the rear of the sear stop to push it all the way down and pry it into the slot at the left. Replace the cocking lever and cocking lever pin.

Hold the cocking leverin your right hand with the pregnant side forward. Put it all the

way down into its slot with the tip pointing back. Put the pin in the left side of the bolt and push in on it. At the same time, pull the cocking lever back until the pin goes through the hole. (This is the easiest way to do it blindfolded.) Now test the firing mechanism. Push the cocking lever all the way forward, then all the way back. (The new type cocking lever cannot be turned all the way forward unless it has been put in with the pregnant side to the front.) Press the sear tip down. You should hear a click as the firing pin snaps forward. If not, the firing mechanism has been improperly assembled.Insert the bolt switch stud

with the small end up.

RestrictedG-27

Place the bolt switch over the stud. For left feed, the narrow end goes to the rear. For right hand feed, the wide end goes to the rear.

Replace the ejector and ejector spring

in the extractor assembly. Slip the spring into its hole with the tail sticking up between the ejector and the side of the extractor. Insert the pin, compress the spring with a pointed tool, and push the pin in just enough to keep the spring down. Then . . . .With your forefinger pressing the pin toward you, force the end of the ejector into its groove until its hole lines up with the pin. Then push the pin into place. .

Replace the extractor assembly

in the bolt. Hold it straight up in your left hand. Push it sideways into the bolt as far as it will go, then let it drop forward.

RestrictedG-28

Nomenclature Function

1 OIL BUFFER SPRING Helps absorb the recoil at the barrel group and push it forward on counter recoil. 2 OIL BUFFER SPRING GUIDE

AND SPRING GUIDE KEYThe spring guide, which is prevented from turning by the spring guide key, holds the oil buffer spring in place 3 OIL BUFFER TUBE Houses the oil buffer parts. 4 FILLER SCREWS (two) Provides openings for filling the oil buffer tube. 5 PISTON HEAD NUT AND PIN Hold the head and valve on the piston rod. 6 PISTON VALVE Closes and opens the holes in the piston rod head. 7 VALVE KEYS (two) Keeps the valve from turning. 8 PISTON ROD HEAD Pushes into the oil to absorb the recoil of the barrel group. 9 TUBE CAP Closes the front of the oil buffer tube. a RELIEF VALVE ASSEMBLY Lets the oil escape if the pressure gets to great. b PACKING GLAND ASSEMBLY Prevents oil leakage around the piston rod. 10 PISTON ROD AND HOOK Connect the barrel extension shank with the piston rod.

Oil Buffer Body Assembly

11 OIL BUFFER TUBE LOCK The front end keeps the accelerator tips from bouncing up; a PROTRUSION The protrusion keeps the oil buffer tube from turning freely. 12 ACCELERATOR

a ACCELERATOR LOCKING LUGS

b ACCELERATOR TIPSServes as an energy transmitter, a locking device, and a timing device. Its functions are explained fully in the discussion of cycle of operations (page G-52). 13 ACCELERATOR PIN Holds the accelerator and provides a pivot for it. 14 LATCH PIN Holds the latch and provides a pivot for it. 16 OIL BUFFER BODY Houses all parts of the oil buffer group. a OIL BUFFER BODY SPRING LOCK Holds the oil buffer group in place when the back plate is off. b Oil BUFFER BODY GUIDES (TWO) Fit into slots in the receiver to help hold the oil buffer group in its place. c SHOULDER Prevent the tips of the accelerator from turning too far down. d BREECH LOCK DEPRESSORS (TWO) Forces the breech lock down by camming down the breech lock pin.

RestrictedG-29

STRIPPING Remove the oil buffer tube assembly

by pushing it back with one hand and pulling it out of the oil buffer body with the other. The tube assembly houses the parts which absorb the recoil of the barrel and barrel extension. The oil buffer spring, which helps take up the recoil and start counter recoil, should be removed only by experienced ordnance personnel. It is powerful enough to cause serious injury when released.Take off the tube lock (11).

Turn the oil buffer body upside down on a table. With one hand, use a tool to pry up the rear end of the tube lock until its rear winged part clears the sides of the circular opening in the slot. With the thumb of the other hand, press down on the front of the tube lock to keep it from springing out. Turn the accelerator (12) back to push the tube lock out of its recess.

The protrusion keeps the oil buffer tube from turning freely. The other end of the tube lock keeps the accelerator from bouncing when it hits the shoulders of the oil buffer body.Remove the accelerator (12)

by drifting out the accelerator pin (13).

The accelerator works in three ways. It is:

An energy transmitter. It transfers energy from the barrel extension to the bolt on recoil, and from the bolt to the barrel extension on counter recoil.

A locking device. Its locking lugs hold the barrel extension back against the oil buffer body during part of the recoil and counter recoil.

A timing device. On recoil, it slows down the barrel extension and speeds up the bolt. On counter recoil, it slows down the bolt and speeds up the barrel extension.

RestrictedG-30

STRIPPING Replace the tube lock.

Put the oil buffer body upside down on a table and hold the lock against it, protrusion down. With the thumb of one hand, press the forward winged part into the circular opening in the slot. With the other hand, raise the rear of the lock just enough to lift the protrusion over the buffer body. Then push the lock forward until the rear winged part snaps into the circular opening.Replace the accelerator and pin.

With the oil buffer body right side up, hold the accelerator with the tips up and the locking lugs to the rear. Push it down between the depressors until it hits the tube lock. Then lay the tips back against the shoulders of the oil buffer body. With one hand, press the pin through the hole. With the other hand, move the accelerator up or down until the pin slips in. (This is the easiest way to do this step blindfolded.)Replace the oil buffer tube assembly.

Sometimes it is necessary to insert a tool under the tube lock to hold its protrusion out of the way. Push the oil buffer tube assembly into place with the piston rod hook facing up.Adjust the oil buffer.

Place the oil buffer group right side up on a table. Press down on it with one hand; with the other, use a tool to turn the oil buffer tube to the left (counterclockwise) until the clicks stop. Then turn it to the right (clockwise) exactly three clicks.

The tube lock protrusion should be in the third notch from the left. Ignore the position of the arrow. It is not an accurate indication of the oil buffer setting.

RestrictedG-31

Nomenclature Function

1 BARREL Gives the bullet direction and spin. a BARREL LOCKING NOTCHES Fit against the barrel locking spring to keep the barrel from turning freely. b CHAMBER Houses the round while it is being fired. (1) SHOULDER OF CHAMBER Support the front end of the cartridge case.

c LANDS (EIGHT)

d GROVESRIFLING Gives the projectile spin.

e BREECH END OF BARREL

f MUZZLE END OF BARREL2 BREECH LOCK Locks the bolt to the barrel extension. 3 BREECH LOCK PIN Holds the breech lock in the barrel extension; hits the depressors on the oil buffer body to force the breech lock down during recoil. 4 BARREL EXTENSION Serves as a connection between the bolt, barrel, oil buffer, and receiver. a BARREL EXTENSION SHANK AND HOOK Connect the barrel extension to the oil buffer tube assembly. (1) SHANK SHOULDERS Provide a surface for the accelerator to lock the barrel extension to the oil buffer body. b BARREL LOCKING SPRING Fits into the barrel locking notches to keep the barrel from turning freely.

RestrictedG-32

STRIPPING Separate the barrel (1) and barrel extension (4)

by unscrewing them.

The barrel establishes the bullet's direction of flight and gives it a right-hand spin for greater accuracy. The barrel extension serves as a connection between the bolt, barrel, oil buffer, and receiver.Remove the breech lock (2)

by drifting out the breech lock pin (3). The breech lock holds the bolt to the barrel extension when the gun is in battery. On recoil, the breech lock pin hits the depressors on the oil buffer body and forces the breech lock down.ASSEMBLY Replace the breech lock.

Hold it in place with the double bevel on top and facing forward. Push the pin into place. (When blindfolded and wearing gloves, you will not be able to tell the double bevel from the single one. In that case just make sure the hole is toward the bottom and the beveled edges are forward.)

RestrictedG-33

Screw the barrel into the barrel extension.

As far as it will go, then unscrew it about one-half turn. This prepares the barrel for the next step.Adjust for headspace.

Put the bolt, with the extractor assembly and switch removed, on the barrel extension and slide it all the way forward. Hold the gun upside down, placing one hand near the breech end of the barrel and the other hand on the barrel extension, with the thumb holding the breech lock down firmly. Do not support the barrel on a bench. With one quick movement, screw the barrel in as far as it will go. Then carefully unscrew the barrel three notches— that is, until you hear three clicks of the barrel locking spring. For this step, you can rest the barrel on a bench. Next . . .... Turn the parts right side up and remove your thumb—the breech lock should fall of its own weight. The head-space adjustment will now be correct enough to permit the recoiling parts to go fully into battery position when the gun is reassembled.

(This method of headspace adjustment is only approximate and must be rechecked after the gun is fully assembled. The procedure and the purpose of the adjustment are fully described on pages G-63 to G-69.)

RestrictedG-34

Nomenclature Function

1 BELT FEED LEVER Pivots from side to side to operate the feeding mechanism. a BELT FEED LEVER LUG Rides in the bolt's cam grooves to move the lever from side to side. 2 BELT FEED LEVER PLUNGER

AND PLUNGER SPRINGHold the belt feed lever in position when the cover is raised. 3 BELT FEED SLIDE Moves from side to side to feed the ammunition belt into the gun. a BELT FEED PAWL SPRING STUD Helps hold the pawl spring in place. 4 BELT FEED PAWL Pushes the new round into the feedway. a PAWL ARM LOCATING PING

b PAWL ARM PINHold the pawl arm in place. 5 BELT FEED PAWL PIN Holds the belt feed pawl and provides a pivot for it. 6 BELT FEED PAWL ARM Prevents double feeding. 7 BELT FEED PAWL SPRING Pushes the belt feed pawl down behind the new round. 8 PISTON ROD HEAD Presses against the cover latch to keep it locked. 9 TUBE CAP Closes the front of the oil buffer tube. 10 COVER LATCH Holds the cover down. 11 COVER PIN AND WASHER Hold the cover latch shaft in the cover. 12 COVER LATCH SHAFT AND LEVER The shaft holds the cover latch. The lever serves as a handle to

turn the shaft and unlock the latch.13 COVER Houses the parts of the cover group. a COVER EXTRACTOR CAM Cams down the extractor assembly on recoil. b COVER LATCH SPRING STUD Holds the cover latch spring in place. c BELT FEED LEVER PIVOT STUD AND COTTER PIN The stud serves as a pivot for the belt feed lever. The cotter pin holds the lever on the stud when the cover is closed. d COVER EXTRACTOR SPRING STUD Helps hold the cover extractor spring in place. e DETENTS Grooves that work with the detent pawl (on the receiver) to hold the cover in any one of three positions when it is raised. 14 COVER PIN AND COTTER PIN Fasten the cover to the receiver.

RestrictedG-35

STRIPPING Remove the belt feed lever (1).

Take out the cotter pin. With one hand, move the tope of the lever over to line up its lower end with the slot in the cover. Use your other hand to lift the lever off its pivot stud, holding your thumb or finger over the plunger and plunger spring (2) to keep them from jumping out.

The belt deed lever, which is pivoted as its lug rides in the cam grooves in the bolt, moves the felt feed slide in and out of the gun to feed new rounds into the feedway.Remove the plunger and plunger spring (2) from the lever.

The plunger and plunger spring hold the belt feed lever in position when the cover is raised.Remove the belt feed slide (3

by pulling it out to the side.

The slide moves in and out of the gun carrying the belt feed pawl, which pushes new rounds into the feedway.Remove the belt feed pawl (4) from the slide.

Hold the pawl down to keep its spring in place while you drift out the felt feed pawl pin (5).

The belt feed pawl slides out over the new round, is snapped down behind it by the spring, and pushes it into the feedway.

RestrictedG-36

Take the pawl arm (6) off the pawl,

and lift the belt feed pawl spring (7) off its stud.

The pawl arm prevents double feeding; if a round is not extracted from the ammunition belt, the pawl arm rides over it, holds up the pawl and thus stops the feeding action..

Remove the cover latch spring (8).

Use a tool to pry out the bottom end of the

cover latch spring and push it over on top

of the cover extractor spring (9). With your

thumb, push the top end of the latch spring

down until it lifts off its stud (13b).

The spring presses against the cover latch to keep it locked..

Remove the cover extractor spring (9).

Use one thumb to keep the spring from popping out. With the other hand, put a pointed too! into the notch in the side of the cover extractor cam (13a) and pry the spring out.

The spring holds the extractor assembly down while a new round is pulled from the ammunition belt. It also cushions the shock when the extractor assembly is cammed up at the end of the counter recoil stroke.Take off the cover latch (10).

Remove the cotter pin, turn the latch shaft lever (12) to the latched position — parallel to the cover — and pull the shaft out the side. The washer and latch will come off.

The latch keeps the cover closed. The cover latch shaft, which holds it, can be turned with the lever to unlock the latch and raise the cover.

RestrictedG-37

Take of the cover (13).

Remove the cotter pin and pull out the cover pin (14). Lift the rear of the cover up and forward to pry the front end out of the trunnion block. Because it is difficult to put back on, the cover should not be removed unless absolutely necessary.ASSEMBLY Replace the latch.

The latch shaft lever should be on the side opposite the charging handle. Put the latch into its recess with the keyway—the little slot inside the hole—toward the top of the cover and the pointed end of the latch against the under side of the cover. Insert the latch shaft with the key —the little ridge along the side of the shaft-lined up with the keyway. Put the washer on the end of the shaft. Insert the cotter pin from the bottom, and bend the ends down carefully to keep them out of the way when the cover is closed.Put on the cover.

Hold the cover in a nearly closed position and push it forward into place. Put the back end all the way down, and force the front end down into position. Then .. . . Insert the cover pin and replace its cotter pin.

RestrictedG-38

Replace the cover extractor spring.

Hook the slotted end of the spring on its stud, with the other end curving away from the cover. With one hand, press the top of the spring all the way back. With the other hand, pry it into the slot to the left by putting a tool between the spring and the cover latch spring stud.

Put back the cover latch spring.

Hold the spring with its lower tip curving into the cover. Put the wide part of the slot over the latch spring stud and force the spring up just enough to hold it in place. With the thumb and forefinger of one hand, hold the top of the cover latch shaft lever toward you to make sure the latch spring rides up over the latch. With the other hand, pry the bottom of the spring up into its slot by putting a tool between the bottom of the spring and the belt feed lever pivot stud.Replace the belt feed pawl arm

on the belt feed pawl. Hold the pawl with its smooth side toward you and its sharp end pointing in the direction of feed—to the right for right feed, to the left for left feed. Put the pawl arm on top, with the pregnant side curving away from you.Replace the belt feed pawl

in the slide. Put down the pawl and pawl arm and pick up the slide—in your right hand if the gun is to feed from the left, or in your left hand if the gun is to feed from the right. In either case, hold it with the open side up and the rounded end toward the direction of feed. Put the small end of the pawl spring over its stud, with the oval loop on top of the spring toward you—away from the pawl arm. Hold the spring in place with the thumbnail of the hand that holds the slide. Use your other hand to place the pawl over the spring, with the pawl arm away from you. Then . . .

RestrictedG-39

Use the thumb which has been holding the pawl to press down on the pawl while you insert the belt feed pawl pin with your other hand. Start the pin in from the side with the arm. Place the belt feed slide in the cover, with the pawl arm on top. Replace the plunger and plunger spring. They go in the upper hole of the belt feed lever for left hand feed, and in the lower hole for right hand feed. (The upper end of the belt feed lever can be recognized by the lug.) Replace the belt feed lever. Set the lever in at an angle with the top end pointing in the direction of feed. Place the plunger against the inside of the cover. Then . . . ...

RestrictedG-40

. . . Straighten the lever until you can put the lower end through the slots in the cover and in the belt feed slide. Push the lever down on the pivot stud as far as you can. Next . . . To get the lever all the way down, turn it as far as you can in the direction that compresses the plunger spring. Finally . . . . . Pivot the lever quickly in the opposite direction while pressing down on it with both thumbs. The plunger and spring will snap down into place. This is the quickest method with most guns, but if the plunger spring is unusually stiff you may have to pry the plunger into place with a screwdriver. Install a cotter pin.

In combat, use a new cotter pin each time—and be sure it is the right size. An old pin may break. A thin pin may keep the gun from feeding properly by letting the belt feed lever drop down too far.

RestrictedG-41

RETRACTING SLIDE GROUP

Nomenclature Function

1 LEVER Pulls back the retracting slide in hand charging. 2 LEVER STUD NUT, WASHER, AND COTTER PIN Hold the lever on the lever stud. 3 LEVER SPRING Keeps the lever forward when not in use. 4 GRIP OR CHARGING HANDLE Is pulled back to hand charge the gun. 5 GRIP BOLT Fastens the grip to the lever. 6 GRIP WASHER prevents binding between grip and lever. 7 BRACKET Holds the retracting slide and provides a slot in which the slide moves back and forth. 8 BRACKET BOLTS, NUTS, AND COTTER PIN (two each) Helps fasten the bracket to the receiver. 9 BRACKET SCREWS (three) Help fasten the bracket to the receiver. 10 RETRACTING SLIDE Works against the bolt stud to move the bolt back in hand charging. 11 LEVERAGE STUD Supports the bottom end of the lever, making it easier to pull back. 12 LEVER STOP Stops the forward movement of the lever. 13 LEVER STUD Fastens the retracting slide lever to the slide and provides a pivot for the lever. 14 PLUNGER AND PLUNGER SPRING Keep the retracting slide forward when not in use. <

RestrictedG-42

STRIPPING The retracting slide can be installed on either side—whichever is convenient for the direction of feed and the place where the gun will be used. These instructions are for stripping the slide from the right and assembling it on the left. The methods can easily be reversed. Remove the lever (1).

from the bracket (7) by taking off the cotter pin, nut, and washer (2). Remove the spring (3). The lever pulls the retracting slide back in hand charging the gun. The spring keep: the lever forward when not in use.Remover the grip (4).

by taking off the grip bolt (5) and washer (6). The grip is simply a handle for operating the lever.

Take off the bracket (7).

If the bracket bolts (8) and bracket screws (9) have been safety wired, as they should be, remove the wire first. Take out both cotter pins. Unscrew the nut from the forward bolt and take the bolt out. Loosen the rear nut. Remove all three bracket screws. Slide the whole bracket forward a fraction of an inch and lift it off the side of the receiver. (Older guns have only one bracket bolt.)

RestrictedG-43

Remove the retracting slide (10).

from the bracket by pushing it out the side.

The retracting slide forces the bolt group to the rear in hand charging.Remove the leverage stud (11)

by unscrewing it from the bracket. Take off the

remaining bracket bolt.

The leverage stud gives the bottom of the lever something to work against, making it easier to pull the lever back.ASSEMBLY

Replace the leverage stud.

Turn the slide over so that it will fit against the left side of the receiver, pointed end of the bracket forward. Screw the leverage stud into the lower forward hole. Then, insert the rear bracket bolt in the top rear hole, with the head of the bolt on the smooth side of the bracket and the beveled edge to the rear. Screw the nut loosely onto the bolt.Put the retracting slide in the bracket.

Place the slide at the rear of the slot, with the lever stop toward the front. Force the slide forward until the plunger and plunger spring (14) go into the notch in the slide.

RestrictedG-44

Replace the bracket.

Put the bracket against the receiver, with the head of the rear bracket bolt through the rear hole on the receiver, and slide the bracket to the rear. Then . . .

. . . Reach in under the front of the top plate to insert the front bracket bolt, its head inside the receiver with the beveled edge forward. Screw on the nut. Put the long bracket screw in the lower front hole and the two short screws in the rear—one in the bottom hole, the other in the second hole from the top. Tighten the screws. Tighten the bolts and insert their cotter pins. Safety wire the bolts and screws.

Replace the grip and grip bolt.

Attach the grip in such a way that it will be on the left side when you hold the lever with its pointed edge away from you. The washer goes between grip and lever.Replace the lever spring.

There are two different lever springs—one for assembling the retracting slide on the right, the other for assembling the slide on the left. The difference is in the position of the bent tip. Using the proper spring, put the bent tip into the hole in the lever—on the side opposite the grip—with the big loop of the spring around the hole for the lever stud.

RestrictedG-45

Replace the lever.

The big loop of the spring goes around the lever stud and the small loop around the lever stop. Replace the washer, tighten the lever stud nut, and replace its cotter pin. The retracting slide group is now correctly assembled on the left side of the receiver.To change the retracting slide from one side to the other: Remove the lever and put the grip on the other side. Take the bracket off the receiver. Take the leverage stud out of the bottom hole and screw it into the top hole. You may have to remove the retracting slide while changing the leverage stud. Turn the bracket over and mount it on the other side of the receiver.

Replace the lever, substituting the correct lever spring. Check to make sure these parts are in the correct position:

1 The grip on the outside of the lever and projecting above the bracket.

2 The pointed side of the lever forward.

3 The bracket bolts on top.

4 One rear screw in the bottom hole and the other in the second hole from the top.

5 The front bracket screw in the bottom hole.

6 The leverage stud on the bottom.

7 The lever stop in front of the lever stud.After changing the retracting slide irom one side to the other, always move the cover latch lever to the side opposite the charging handle. Otherwise, the charging handle may hit the cover latch and force the cover partly open. The gun will, not fire unless the cover is tightly latched to hold the belt feed lever lug down in the bolt's cam grooves.

RestrictedG-46

Nomenclature Function

1 BELT HOLDING PAWL Holds the ammunition belt in the feedway. 2 BELT HOLDING PAWL Force the belt holding the pawl up behind the next round. 3 BELT HOLDING PAWL PINS Hold the belt holding pawl and the cartridge stops. > 4 FRONT CARTRIDGE STOP Holds the front of the cartridge in the correct position . 5 LINK STRIPPER Strips the links off the cartridge case. 6 REAR CARTRIDGE STOP Holds the rear of the cartridge in the correct position.. 7 RIGHT-HAND REAR CARTRIDGE STOP ASSEMBLY Serves as a combination rear cartridge stoop, link striper, and short round eliminator when the gun feeds from the left.. 8 EXTRACTOR SWITCH AND SWITCH PIVOT The switch cams the extractor assembly down at the beginning of counter recoil to align the new round with the chamber. 9 EXTRACTOR SWITCH SPRING Returns the switch to its original position. 10 EXTRACTOR SWITCH PIVOT NUT AND COTTER PIN Fasten the extractor switch to the receiver. 11 TRIGGER BAR Pushes down the sear when the trigger is pressed. 12 TRIGGER BAR PIN Holds the trigger bar and provides a pivot for it.. 13 RECEIVER Houses the working parts of the gun. a TRUNNION ADAPTER Serves as a front mounting for the gun. b DETENT PAWL Holds the cover up by pushing into the detents in the cover. c TRUNNION BLOCK Provides a bearing for the breech end of the barrel; forms the bottom of the feedway; serves as a spacer for the side plates. d REAR MOUNTING HOLES Serve as the rear mounting for the gun. e REAR TRIGGER BAR STOP Holds the trigger bar. f TOP PLATE BRACKET

(1) FRONT AND REAR COCKING LEVER CAMS (OR "V-SLOT")Cam the cocking lever backward and forward. g BOLT STOP Provides a means of locking the bolt to the rear. h EXTRACTOR CAM Cams the extractor assembly up on the last part of counter recoil. i BREECH LOCK CAM Cams the breech lock up on counter recoil; prevents forward movement of the oil buffer body; holds the barrel extension down. 14 BARREL JACKET House the barrel and holds the front barrel bearing. Its holes insure uniform cooling of barrel 15 FRONT BARREL BEARING Supports the front end of the barrel and prevents whip. In firing, the barrel slides through this bearing and the trunnion block.

RestrictedG-47

STRIPPING Remove the belt holding pawl (1) and springs (2).

Keep the pawl pressed down with one hand while you pull out the belt holding pawl pin (3) with the other.

The belt holding pawl holds the ammunition belt in position while the belt feed pawl (in the cover group) moves out over the new round

Take off the cartridge stops

by pulling out the other belt holding pawl pin. On a gun feeding from the right, this will release the front cartridge stop (4), link stripper (5), and rear cartridge stop (6). On a gun feeding from the left, it will release the front cartridge stop (4) and the right-hand rear cartridge stop assembly (7).

On a gun feeding from the right, the front and rear cartridge stops are installed on the left side to hold the new rounds in position. The link stripper, between them, pulls the links from the cartridges. On a gun feeding from the left, only a front cartridge stop is installed—this time on the right side. The right-hand rear cartridge stop acts as a combination link stripper, short round eliminator, and rear cartridge stop.

Remove the extractor switch (8) and its spring (9).

Take off the cotter pin and nut (10). Holding the rear of the switch against the receiver, push the switch pivot in until the looped end of the spring snaps up above the switch. Then . . .Hold the looped end of the spring while you remove the switch. Lift the spring out of its recess. On recoil, the rear of the extractor switch is pivoted downward by the lug on the extractor assembly. The switch is then forced back into position by its spring, and on counter recoil it cams the extractor assembly down to aline the new round with the chamber.

RestrictedG-48

Remove the trigger bar (11).

Use a tool to pry the stud on the rear of the trigger bar pin (12) out of the hole in the receiver. Then . . .ASSEMBLY Replace the trigger bar.

Hold the rear end of the trigger bar in your right hand—long end forward, bowed side up. Push it in place, just to the right of the top plate bracket, until the rear of the trigger bar is about a quarter inch behind the rear trigger bar stop (13e). Insert the trigger bar pin, holding the handle of the pin down and slightly forward so that the ridge along the pin fits through the keyway in the hole. Move the trigger bar backward or forward until the pin slips into its hole in the trigger. Then pivot the pin to the rear until its stud snaps into the hole in the receiver.Replace the extractor switch and its spring.

First, put the switch spring into its recess in the side of the receiver, loop end forward. Put the bent tip of the spring through the little hole in the side plate, letting the long end of the spring stick above the recess. Hold the extractor switch in your right hand. Then . . .

RestrictedG-49

Hold the bottom half of the spring in place with one finger while you put the switch pivot through the hole in the side of the receiver. Make sure that the front end of the switch is above the extractor cam, and that the lug at the rear of the switch is resting on the spring. Finally . . .

. . . Hold the switch against the receiver with both fingers while you pivot its rear end down into place. The top of the spring will snap into the recess. Replace the nut, being careful not to screw it too tight. Make sure the switch operates properly.

Replace the cartridge stops

and insert the belt holding pawl pin that holds them. If the gun is to feed from the right, install the front and rear cartridge stops on the left, with the link stripper in between. (The cartridge stops are stamped FRONT and REAR. The rear stop is always shorter.) If the gun is to feed from the left, install the front cartridge stop and right-hand rear cartridge stop assembly on the right.

Replace the belt holding pawl and springs

on the right side for right feed, or left side for left feed. Seat the springs in the two holes and place the pawl on top. Press the pawl down with one hand while you insert the pin with the other.

RestrictedG-50

In an emergency, the gun can be stripped with nothing but its own parts as tools. Use the point of a cartridge or the cocking lever pin to depress the oil buffer body spring lock.

Use the cocking lever pin to drift out the sear stop pin and accelerator pin.

Use the flat tip of the cocking lever as you would use a screw driver to remove and replace the sear stop, oil buffer tube lock, the cover latch spring, and cover extractor spring. Use the oil buffer tube lock to pry the handle of the trigger bar pin out of its hole in the side of the receiver.

Use the sear stop pin to drift out the belt feed pawl pin.

But use these methods only when absolutely necessary and take care not to damage the parts used as tools. Never use the driving spring rod assembly as a tool.

HEATERS

In bombing missions at high altitude, where the temperature may drop to 50 degrees below zero, an electric heater is sometimes clamped over the cover of the gun to keep the parts from "freezing" together. There are two models of the heater—one with a side plate extending down the left side of the gun, the other with the side plate on the right. The part that extends down must be opposite the charging handle.

To install a heater, turn its two clamps straight up. Raise the cover of the gun, and slide the heater down on it as far as it will go. Turn the top clamp down and back until it snaps into the catch; turn the lower clamp up and back into the catch.

The heater turns on when you plug it into the bomber's electric output. Do not leave the heater connected when it is off the gun.

RestrictedG-51

Transcribed and formatted by Thomas Wildenberg for the HyperWar Foundation