Chapter XXIII

Cargo Handling for APAs, AKAs, APs, AKs, XAPs and XAKs

Index

| Section 1. | Cargo Handling Teams |

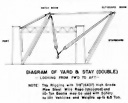

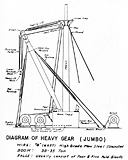

| Section 2. | Cargo Handling Rigs |

| Section 3. | Testing Cargo Handling Gear |

Section 1. Cargo Handling Teams

- In Amphibious Operations it is necessary to handle the Combat Loaded Cargo and the cargo for Garrison Forces under the most difficult unloading conditions by placing it into LSTs, Landing Craft, and Landing Boats alongside ships lying-to or anchored in open roadsteads. Unless this cargo is unloaded expeditiously, it may mean the difference between the success or failure of the Amphibious Operation, and further, it may result in the loss of the Transports or Cargo Vessels themselves.

- Combat cargo handling by ships engaged in or supporting, an Amphibious Operation, is a "Military Evolution" which requires trained cargo handling teams just as much as the battery of the vessel requires trained gun crews.

-

Each APA, AKA, AP and AK of this force having naval crews will organize

cargo handling teams composed of Winchmen, Hatch Tenders, and deck

Petty Officer Supervisors. The Standard Cargo Handling team based

on a five (5) cargo hatch ship will be composed of:

20 Winchmen 10 Hatch Tenders 2 Deck Petty Officers for forward hatch group 2 Deck Petty Officers for after hatch group 2 Deck Petty Officers for controlling boats coming alongside - The Commander Operational Training Command, U.S. Pacific Fleet, has set up a Winchmen and Hatch Tender Training School at San Francisco at which school cargo handling teams will be trained.

- Cargo Handling teams composed of Naval personnel will be trained by the Winchmen and Hatch Tenders School at San Francisco and set up in a pool from which the cargo handling teams for merchant crew manned XAPs and XAKs will be taken.

- As the opportunity for training cargo handling teams is very limited and can only be accomplished during the short periods of Amphibious training and loading and unloading, vessels of this force will take advantage of the training facilities provided by the Winchmen and Hatch tenders School whenever possible.